How to Manage Joinery Lead Times and Reduce Costs at the Same Time

Why Managing Lead Times and Costs is Essential for Your Custom Joinery Success

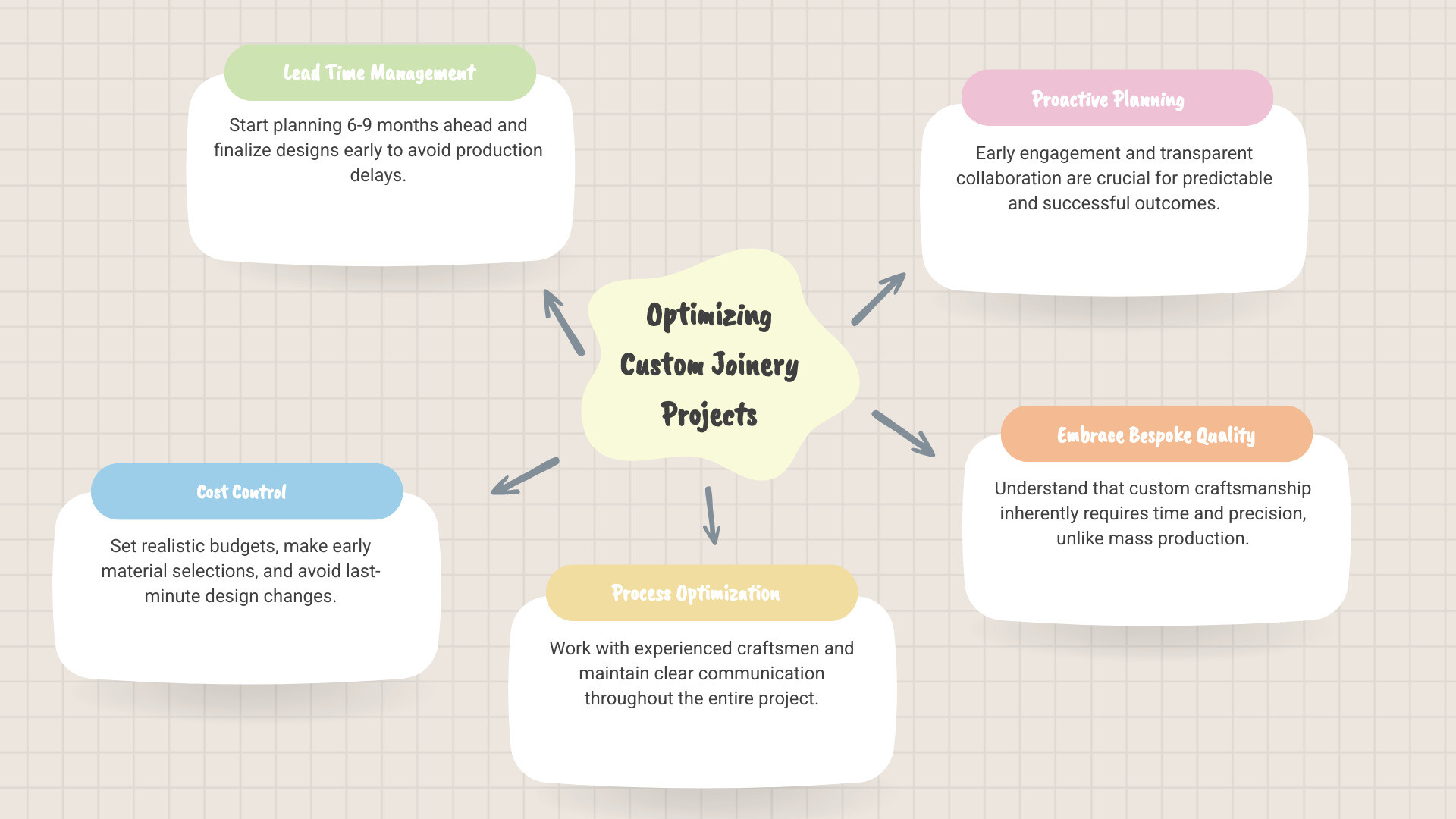

For any successful renovation or new build, tips for managing custom joinery lead times and costs are crucial. Custom projects can take 6-20 weeks depending on complexity, with costs varying significantly. Proactive management of the timeline and budget is the key to a smooth process and a stunning result.

The challenge with custom joinery is that it's inherently bespoke. Each piece requires individual design, precise manufacturing, and skilled installation. Unlike mass-produced alternatives, there's no rushing quality craftsmanship. However, with the right approach and experienced partners, you can achieve exceptional results without unpredictable delays or budget blowouts.

At G&M Craftsman Cabinets, our decades of experience working with clients across the Sunshine Coast have shown us that transparency and early planning are the foundations of every successful project. Understanding the factors that influence both timeline and budget allows you to make informed decisions, protecting your investment while bringing your vision to life.

Your Guide to Managing Custom Joinery Lead Times and Costs

Bespoke joinery is an investment that transforms spaces with functionality and beauty. At G&M Craftsman Cabinets, we specialise in luxury custom-made joinery for the Sunshine Coast, backed by 100 years of combined experience. We believe understanding the process is the first step to a successful project. Learn more about our process to see how we bring visions to life.

Why Bespoke Joinery Takes Time: The Craftsmanship Factor

A common question is, "Why do custom joinery projects take so long?" The answer lies in the difference between mass-produced and bespoke items. A flat-pack cabinet is available immediately because it's standardised. Bespoke joinery, however, is a creative and precise process where every piece is made to measure for a specific space.

The journey from concept to completion is multi-staged. It begins with detailed design consultations and precise on-site measurements. We then source high-quality materials and specialised hardware from trusted suppliers like Blum and Silestone. After you approve the detailed shop drawings, our craftsmen begin the meticulous manufacturing process. Unlike an assembly line, each component is built individually, followed by stringent quality control, finishing, and finally, expert installation. Each step requires artistry and attention to detail, which is why quality craftsmanship cannot be rushed. Find more about our custom cabinetry services.

External Factors Influencing Your Project Timeline

While our processes are optimised, the industry is susceptible to external forces that can impact timelines.

Labour and Material Shortages

Labour shortages for skilled trades and global supply chain disruptions can extend project timelines. Delays in sourcing timber and other critical components, along with rising material costs, are industry-wide challenges that can affect production schedules.

Increased Demand

As demand for quality bespoke joinery grows, lead times naturally extend. A workshop with a long queue of projects means new orders are scheduled accordingly, so it's wise to plan ahead.

The Power of Strong Supplier Relationships

At G&M Craftsman Cabinets, our long-standing relationships with trusted suppliers like Furnware Dorset, Blum, Titus Plus, Kethy, Hettich, and Häfele are paramount. These partnerships help us prioritise orders, manage costs, and ensure a consistent supply of high-quality materials for our luxury joinery.

Actionable tips for managing custom joinery lead times and costs

Proactive steps can ensure a smoother, more predictable project. These tips for managing custom joinery lead times and costs empower you to be an informed partner.

- Engage Early: For large projects, contact us up to 12 months in advance. This allows ample time for design, material sourcing, and scheduling.

- Be Decisive in Planning: The design stage is critical. Be clear about your vision and functional needs. The more decisive you are, the faster we can move to manufacturing.

- Finalise Designs: Avoid significant changes after designs are approved. Alterations can cause a ripple effect on material orders and production schedules, adding time and cost.

- Communicate Clearly: Maintain open communication with our team. We believe transparency is key, so don't hesitate to ask questions.

- Set Realistic Expectations: Understand that quality custom work takes time. We provide realistic timelines from the outset and prioritise honesty about the process.

Smart budget tips for managing custom joinery lead times and costs

Custom joinery is an investment, but smart choices can help manage the final cost without compromising on quality.

Key Considerations for Managing Costs

- Material Selection: Your choice of material is a major cost driver. Solid timber is typically more expensive than high-quality laminates or MDF. We can help you select cost-effective materials that don't sacrifice durability or aesthetics.

- Design Rationalisation: Intricate details and curves add complexity and cost. Streamlining designs, such as opting for a combination of drawers and cabinets, can be more budget-friendly.

- Hardware Choices: We partner with top-tier brands like Blum and Hettich. While features like soft-close mechanisms are invaluable, we can help you steer their ranges to find the best balance for your budget.

- Long-Term Value: Our cabinetry is built for longevity, saving you money on repairs and replacements over time. Engaging a cabinet maker like us directly is often more cost-effective than going through a retail company with added overheads.

To see the quality of our work, view our portfolio for inspiration.

The G&M Difference: How Our Process Delivers Value and Transparency

At G\&M Craftsman Cabinets, our tips for managing custom joinery lead times and costs are embedded in our comprehensive 6-step process, designed for clarity and exceptional results.

Our Integrated 6-Step Process

Our process is thorough, transparent, and client-focused, setting us apart as Sunshine Coast cabinet makers.

- Budgeting & Consulting: We work with renovators and builders across the Sunshine Coast, from Noosa to Pelican Waters. We review architectural plans to ensure designs are achievable and provide realistic costings.

- Planning & Design: Our consultants help you plan your project, sourcing the right hardware and finishes from partners like Blum and Häfele to meet your goals and ensure functionality.

- Manufacture: We are true craftsmen. Everything is made in-house to the highest level of detail, with knowledge passed down through generations.

- Installation: Our tradespeople are craftsmen who hone their skills over time. We treat every project as our own, ensuring a perfect, seamless finish.

- Project Management: Our experienced team ensures all related trades are booked and briefed. We prioritise communication, keeping you updated every step of the way.

- Maintenance: We can help with repairs and maintenance to keep your joinery looking new for years. Proper care is also essential; see our Care & Maintenance Tips.

This integrated approach allows us to deliver projects efficiently without compromising on bespoke quality. To learn more, explore our unique process.

Expert Guidance, Quality Results – Book a Consultation

Your custom joinery journey doesn't have to be overwhelming. With the right guidance and proven tips for managing custom joinery lead times and costs, you can achieve a stunning result on time and within budget. At G&M Craftsman Cabinets, we've transformed hundreds of Sunshine Coast homes with luxury, bespoke joinery, and we know that success starts with planning and transparency.

Custom joinery is an investment in your home's beauty, function, and long-term value. What sets us apart is our commitment to personalised service. We keep you informed at every stage, from the initial design consultation to the final installation by our skilled craftsmen. We use only the finest materials and hardware from trusted partners like Blum, Häfele, and Silestone, ensuring a quality finish that lasts.

Don't let uncertainty hold you back. Our experienced design consultants are ready to help you steer the possibilities of custom joinery, creating a realistic plan that brings your vision to life.

Book a consultation with our design experts today and find how our proven process delivers precision, quality, and care.